Training & Consulting – Learn something new

Training & Consulting

Overview: Training & Consulting

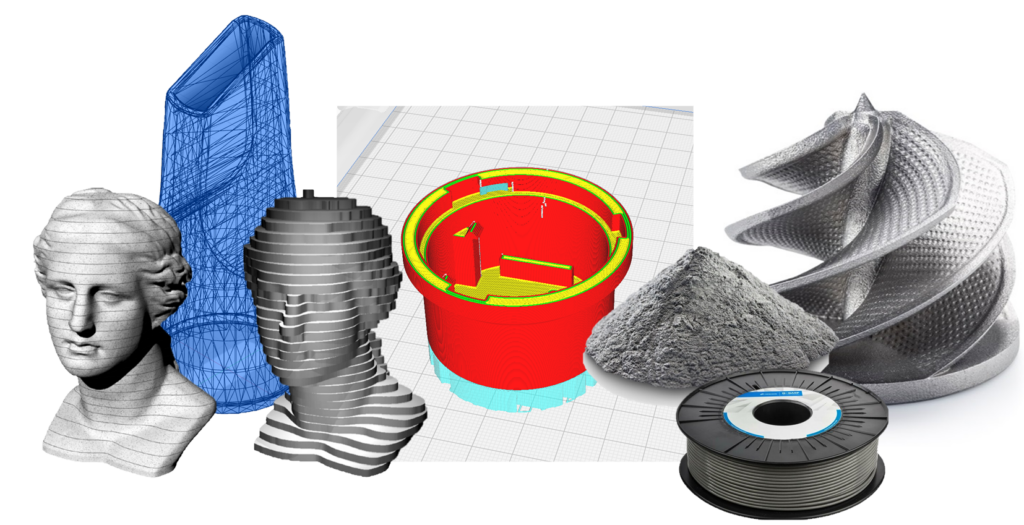

We understand that end-to-end traceability and Additive Manufacturing are complex topics: that is why we offer consultancy and training to help you integrate these technologies into your workflow. Lack of managerial understanding surrounding the application, advantages and complexity of additive manufacturing are common hurdles to its adoption: subsequently, our modules can be tailored for newcomers to 3D printing technology and for experts, and cover the fundamental topics needed for developing complete workflow and supply chain traceability. With our expertise, we help you build an efficient, streamlined digital workflow to enhance your manufacturing processes – across multiple areas.

You can also book our trainings via our partner Fastlane:

You can also book our trainings via our partner Fastlane:

And TÜV NORD Academy:

And TÜV NORD Academy:

You are interested in 3D printing and want to get a general overview? You want to find out what is possible at all? This seminar will inform you about the basics of additive manufacturing, a young technology that is already being used successfully in many industries. Learn about opportunities and challenges, the most industrially relevant processes, their features and much more. All of this will be concretised with accompanying application examples from industry.

You want your components to be traceable throughout the entire production process? You want to protect yourself and your components from product piracy? In this seminar, you will gain insights into how you can introduce traceability into your manufacturing process and what advantages the traceability of components brings for the entire value chain. You will learn about the risk of product piracy and will be presented with tools and solutions to protect yourself and your products from it.

Do you want to mark your components consistently? Labels can come off and handwritten markings can be faulty, illegible and inconsistent. In this seminar you will gain an insight into Direct Part Marking. This includes an overview of machine-readable codes and their structure. Possible marking technologies will be presented, with the most common methods (inkjet printing, laser marking and needle embossing) and direct marking during additive manufacturing being discussed in more detail.

Are you unsure whether and how you can ensure quality in your additive process? With good quality management, you can contribute significantly to the success of your company. You will learn to recognise risks and the causes of these effects in your production system: the Ishikawa diagram, also known as cause-effect diagram, is used for this purpose. You will learn to qualify your manufacturing processes, verify component requirements and ensure quality throughout the entire value chain. The seminar is based on the new DIN EN ISO/ASTM 52920 standard.

You have decided in favour of additive manufacturing of components, but you are not sure how to get from the design to the finished item? Now you are faced with the make-or-buy decision. In this seminar you will develop the foundations for decision-making. You will learn how to select the right suppliers, what qualifications your employees need, what investment costs you will face and other factors for building a qualified supply chain.

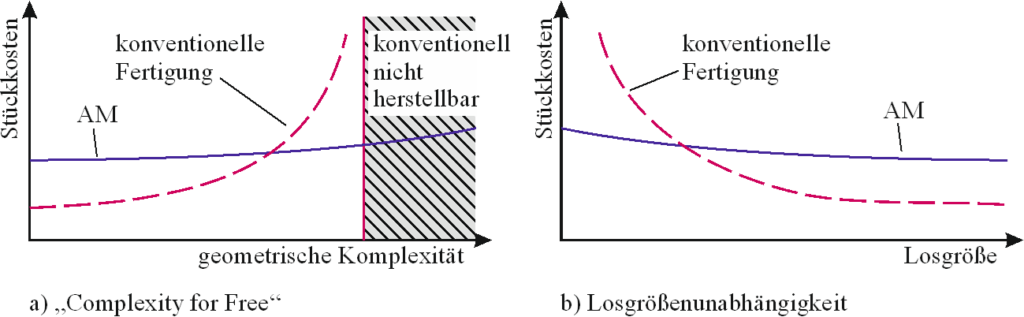

You already know the potentials of 3D printing, are convinced of the advantages and would now like to find out which of your components can be profitably manufactured additively? Which processes are suitable and what savings can you expect? In this seminar you will learn which of your existing components can be considered for additive manufacturing. Both technical and economic aspects will be taken into consideration. Participants can bring their own components and questions and contribute to the discussion.

Are you interested in 3D printing but wondering what economic benefits additive manufacturing can bring to your business? In this module you will learn what economic benefits additive manufacturing can offer you. In parallel, the important topics of environmental protection and resource efficiency will be addressed, and you will learn what resource-efficient on-demand manufacturing can look like.

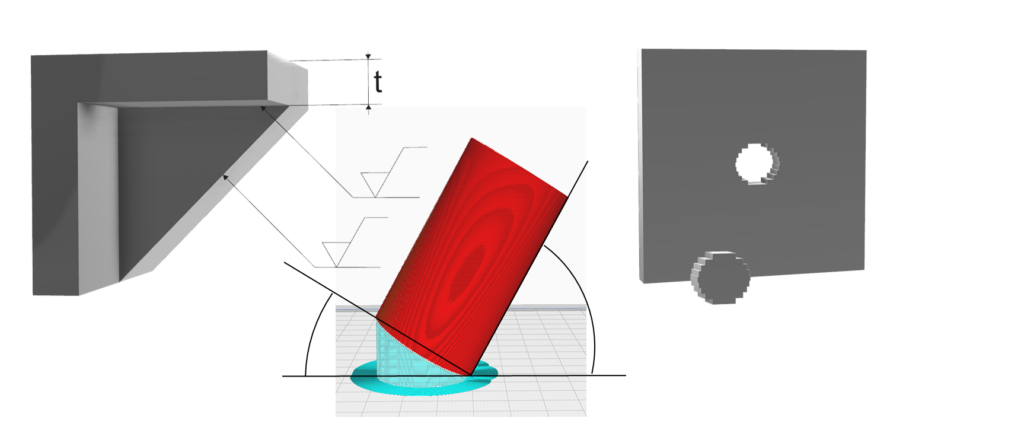

Additive manufacturing offers many new design and construction possibilities, but the full potential cannot be achieved with design guidelines for conventional manufacturing processes. Building on VDI 3405-3 and DIN EN ISO/ASTM 52911, participants learn in this seminar how to optimise components for the additive process. They learn process-specific guidelines as well as how to consider the support structures in the design of the component. Participants can bring their own components and questions and contribute to the discussion.

The digital product passport occupies a central position as part of an EU-wide sustainability strategy. With the aim of working towards a climate-friendly, resource-efficient economy, better access to sustainability-related information throughout the entire product life cycle is to become mandatory. This should facilitate recycling and the choice of sustainable products. Learn here how to make your processes and products fit for the digital product passport.