Part Marking – How to mark your parts successfully

Part Marking & Unique Identification

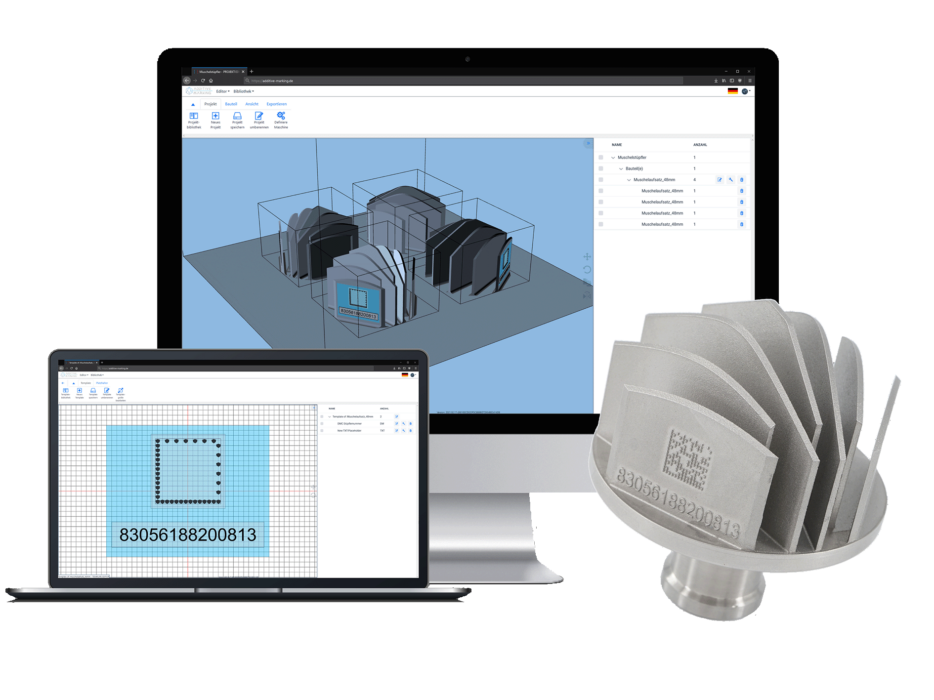

The Additive Marking Serializer

Effortlessly enhance the traceability of components with our advanced Serializer. This tool automatically generates markings, accommodating various specifications crucial for end-to-end component traceability. Users can define marking parameters identifiers and apply to groups of components as required. Apply machine-readable codes, text and graphic-based markings onto your parts as needed. Elevate your manufacturing processes, achieve greater operational efficiency and support quality management through application of our Serializer.

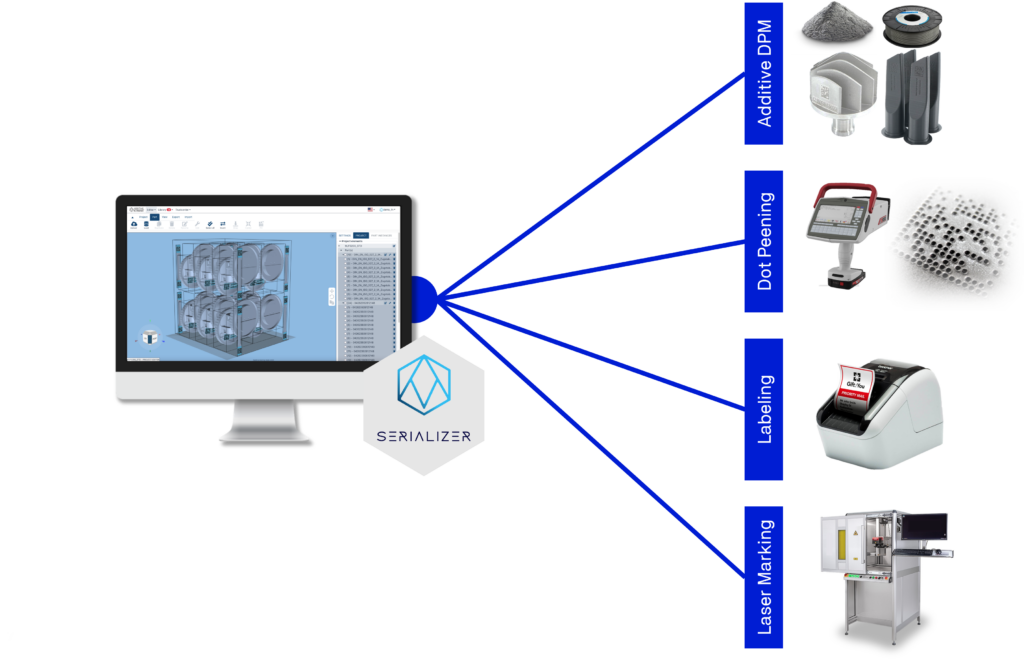

A Solution For All Manufacturing Methods

For Additive Manufacturing, our markings are seamlessly integrated into 3D models during the digital workflow. But of course, our marking technology is not only confined to 3D printing. For conventional manufacturing types, such as CNC machining or milling, the marking process can be adapted to best suit your needs: dot peening, laser marking and adhesive labels are all possible alternative marking techniques. Check out the toggle below for more detailed information on these processes.

Additive ManufacturingIf you are serializing components as part of your 3D printing process, our marks can be directly integrated into your part in the build job at no additional cost. These human or machine-readable markings can be printed onto various materials with different topologies. The use of marking templates also ensures reusability of generated labels, enabling you to design company-specific combinations of marks. These can be applied universally across your product portfolio. |

|

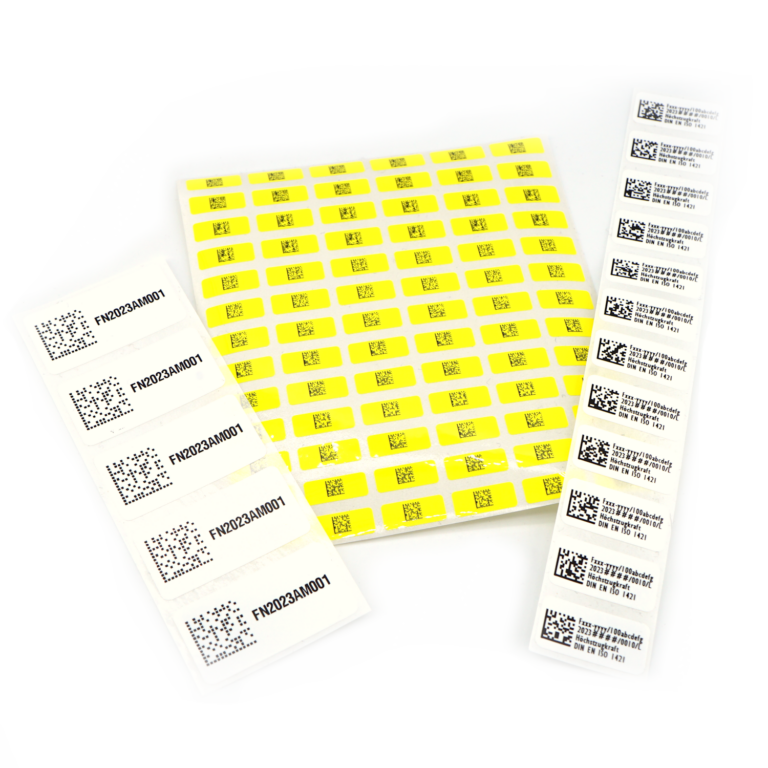

CNC Machining, Milling and other manufacturing methodsWe offer a range of marking solutions - including laser marking, dot peening and adhesive labels - which can be applied to components of various sizes, materials and shapes. We can also integrate our serialize into your ERP and MES systems to provide additional functionality for rapid part identification, tracking, quality management and certification. |

|

Additive ManufacturingIf you are serializing components as part of your 3D printing process, our marks can be directly integrated into your part in the build job at no additional cost. These human or machine-readable markings can be printed onto various materials with different topologies. The use of marking templates also ensures reusability of generated labels, enabling you to design company-specific combinations of marks. These can be applied universally across your product portfolio. |

|

CNC Machining, Milling and other manufacturing methodsWe offer a range of marking solutions - including laser marking, dot peening and adhesive labels - which can be applied to components of various sizes, materials and shapes. We can also integrate our serialize into your ERP and MES systems to provide additional functionality for rapid part identification, tracking, quality management and certification. |

|

Your Advantages

Brand Protection

Safeguard your products against piracy and counterfeiting by integrating authenticating features and watermarks into your products. Validated parts help protect the integrity of your brand.

Traceability through Machine-Readable Codes

Our markings are robust and maintain machine readability even after blasting or dyeing. The connectivity between the part and its digital twin can therefore be effectively managed throughout the product's lifecycle.

Inventory and Order Management

Unify your supply chain processes with machine-readable codes to link physical parts to systems like ERP or Digital Product Passports. Our solutions help you optimise your inventory and order management by providing quick access to extensive part processing history.

Cloudbased

Dedicated Server