Traceability and us – learn about our company and vision

Additive Marking Is Your Complete Solution Provider for End-to-End Component Traceability

Let's SERIALIZE | Let's AUTOMATE | Let's TRACE

What We Do

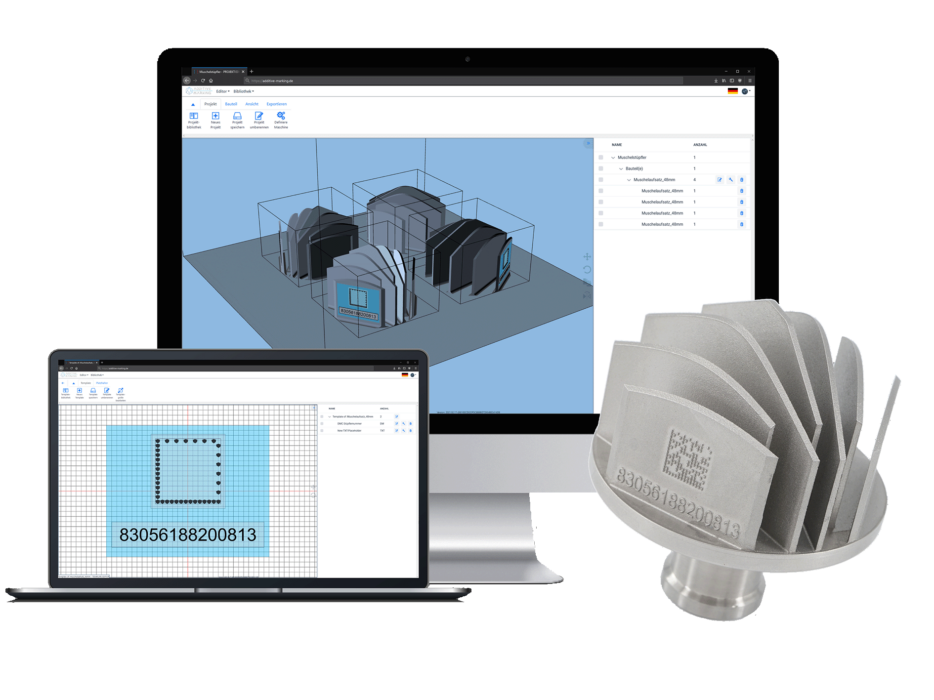

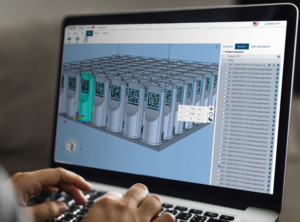

Additive Marking is your complete solution provider for the End-to-End Traceability of components; our technology enables the rapid generation of unique, machine-readable markings to support the complete lifecycle management of parts - from manufacture through to recycling. Whether your production process is Additive Manufacturing, CNC machining/milling or something else entirely, we provide traceability solutions tailored to your specific needs.

Our Areas of Expertise

- End-to-End Traceability

- Machine Code Scanning

- Direct Part Marking

- Digital Product Passports

Functional Areas

- Product Lifecycle Management

- Workflow Automation

- Quality Management

- Enhanced Brand Protection

Our Software Suite

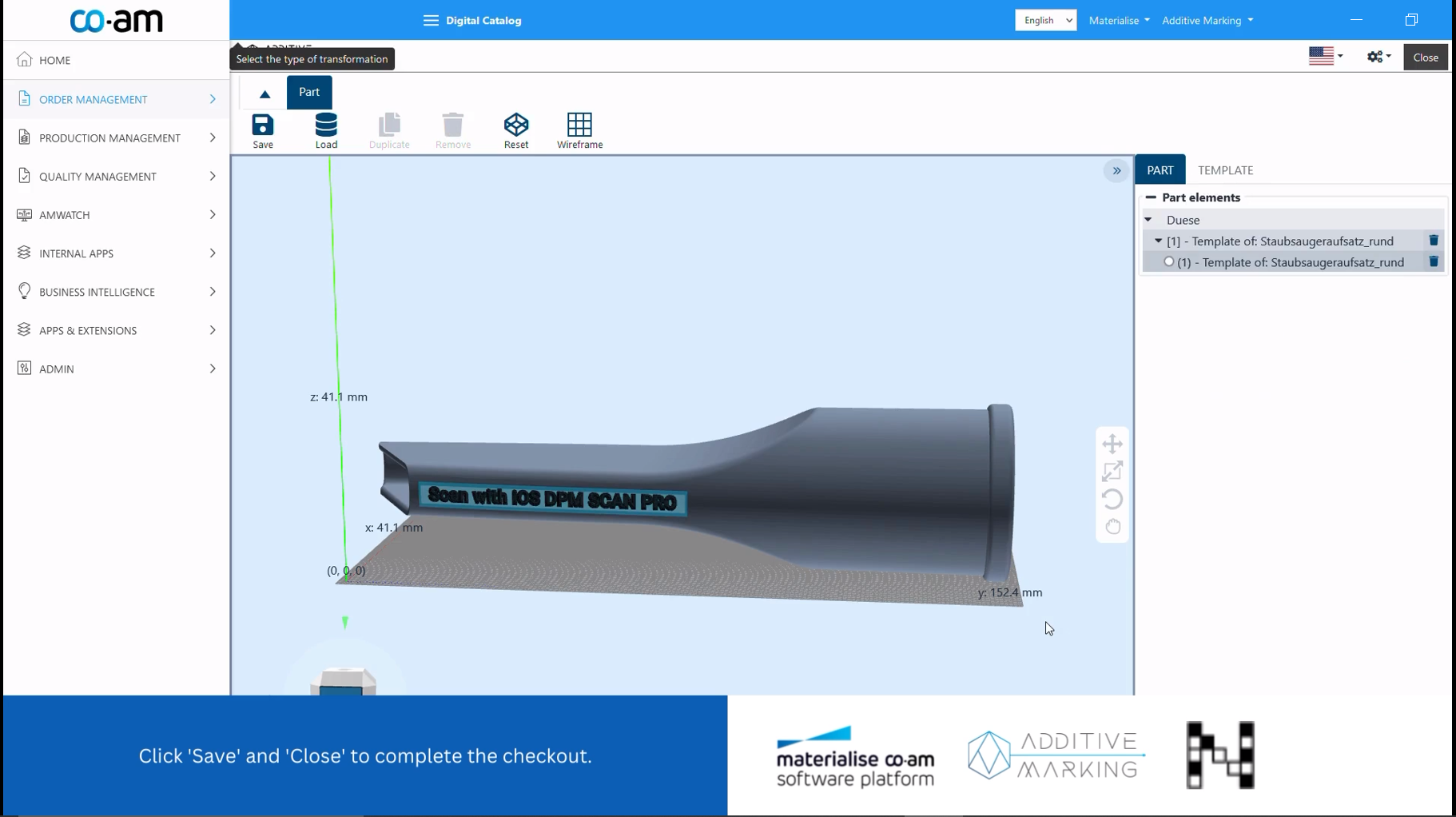

The Additive Marking Suite comprises of our DPM Scan Pro, Serializer and DLM TrustCenter. These modules provide a range of functionalities including digital inventory management; part serialization and integrated labelling; Digital Product Passports; build job process tracking and status setting; digital twin connectivity and data management (including quality assurance certification and reports). For Additive Manufacturing we also offer an additional certification service, iAM-Approved, for component and process certification against DIN EN ISO/ASTM 52920 through collaboration with TÜV NORD.

Serializer

DPM Scan Pro

TrustCenter

A Wealth of Experience

With over 39+ years of combined experience in the Additive Manufacturing field, we are specialists in the application of this rapidly advancing technology for supply chain optimisation and transparency. Subsequently, we also offer consulting and training programmes to support you in your adoption of Additive Manufacturing and Traceability solutions, helping you maximise your manufacturing potential and achieve greater satisfaction for the end customer.

Of Combined Experience

Completed

Our Timeline

We developed our solutions from the ground-up

Origins in Additive Manufacturing

Our solutions developed out of the Additive Manufacturing field. Our experience of being unable to track which build job a part was sourced from, and other quality-implicating factors such as part location within the build chamber and machine type, led us to develop a solution which would allow us to better monitor quality and support continuous process improvement.

How to ensure quality?

Without a market solution for certifying the compliance of 3D printed parts against appropriate industry standards, we identified that this was a significant barrier to additive manufacturing adoption in specialist industries such as medical, automotive, aerospace and the like.

Additive Marking Suite arrives

After refining our use cases, the Additive Marking Suite was built: this is our traceability “kit” which enables you to create a completely transparent Additive Manufacturing supply chain.

Expanding beyond Additive Manufacturing

As our software evolves, we are expanding our solutions beyond the Additive Manufacturing sector to serve other production processes, including CNC machining, milling, and more.

Sustainability Solutions

The future is circular: that is why our services are prepared for the sustainable transition. As the need for production transparency increases, we are rising to meet tomorrow’s needs: from Digital Product Passports to paperless workflows, we are here for your every tracebility need.

Explore our success stories