COP28: How Digital Product Passports Add Value And Support Sustainability

- Leila Bracken

- December 6, 2023

- News, Opinion, Uncategorized

- additive manufacturing, COP28, Digital Product Passport, End-2-End, Process Optimisation, Procurement, Regulations, supply chain, Sustainability, traceability

- 0 Comments

How End-To-End Traceability Supports Value Generation Across The Supply Chain

It’s December everyone! And you know what that means?

Actually, I’m not just talking about Christmas. We are midway through COP28, the United Nations’ Climate Change Conference; COP28 will be the first official “Global Stocktake” of progress towards the sustainability goals laid out at COP21 in 2015.

With nations, businesses, NGOs and the public all considering how they can do their part to support the global sustainability goals – whether it’s reducing emissions, enhancing biodiversity or limiting material wastage – we thought we would reflect on how component traceability can support the sustainable transition.

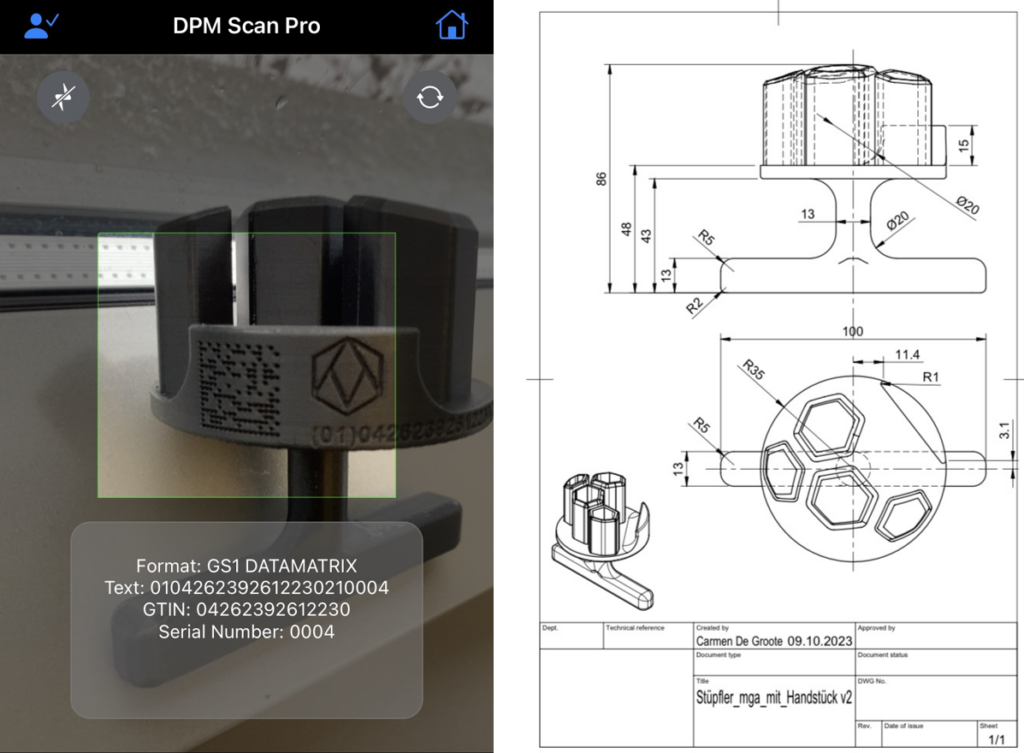

While we specialise in software for Additive Manufacturing and other advanced manufacturing technologies, our core service is to provide component traceability technology. We do this by bringing in machine-readable, direct part markings onto components – either into the digital part file or post-process through a variety of different marking technologies – and enabling digital connectivity via our mobile-app based scanning solution. The digital link established can then be linked to whichever end point is needed to support the lifecycle management of a component: an ERP system, a digital warehouse, a website, and so forth.

At Additive Marking, we are using our traceability expertise to develop a dynamic Digital Product Passport which connects directly to physical components. Through our software, customers can input relevant product information – ranging from sustainability metrics through to technical drawings – which are then automatically formatted into a Digital Product Passport which various supply chain stakeholders can view as needed.

So, What Is A Digital Product Passport?

A Digital Product Passport (DPP) is a digital tool which combines product data from across the value chain. Information about raw materials, manufacturing location, order number, recycling information etc. can be made available to view by relevant stakeholders. DPPs enable the complete, end-to-end traceability of products and provide numerous benefits. You can read more about what a DPP is here.

Perhaps the biggest development in this field for 2024 is the establishment of the Ecodesign for Sustainable Products Regulation (ESPR). Forming out of several existing EU directives and driven by the need to make products more sustainable in line with the 2020 Circular Economy Action Plan, DPPs will contain holistic information about a product’s lifecycle, including sustainability metrics and other information relevant to its manufacture, use, and disposal.

While the DPP’s primary purpose is to “improve their circularity, energy performance and other environmental sustainability aspects” of manufactured products, we encourage industries to also consider how these digital product profiles can be used to add value to internal processes, as well as the wider supply chain.

Adding Value With The Digital Product Passport

Although new regulations are typically met with a groan from industry, the DPP has the potential to support digitisation and streamlining of internal company processes, enabling cost savings and the generation of value; the DPP is a way of agglomerating large volumes of information into a concise and understandable format, enabling the transfer of product information along the value chain. Our Additive Marking Suite is well positioned to bridge the market gap for a traceable, accessible and integrated DPP for products. Although there are numerous documents already outlining the features and functions of DPPs, questions around their application remain. So, what are these questions?

How Will The Digital Product Passport Benefit Manufacturing Workflows?

In addition to the legally required sustainability information, manufacturers might also choose to use the DPP as a workflow automation tool: the setting of build status and machine information for example is a capability already integrated into the Additive Marking Suite, enabling engineers to optimise their shopfloor management and support cost savings. Other supporting documents such as technical drawings, standards conformance certificates and so forth, can also be integrated into the DPP. Once the digital profile exists, as much information can be added as needed by stakeholders; through effective access management, you can then make specific information available to particular stakeholders.

What Information Is Essential For Which Stakeholders? Who Will Have Access?

With vast amounts of product information available, deciding what information is relevant to which stakeholders is a complex task. The ESPR emphasises how the DPP should “provide information about products’ environmental sustainability” to both “consumers and businesses” – but in reality, numerous other stakeholders exist. While some information is required by law to be made public, other information is relevant to only a few stakeholders in the value chain. Subsequently, it is essential to adapt the DPP to specific users, and for that we must think beyond the traditional “supplier, manufacturer, consumer” mindset. Other stakeholders to consider include economic operators, waste carriers and the European Commission. To overcome access challenges, we envision a mixed private/public accessibility to the DPP where specific fields are made available to view where a stakeholder sits in the supply chain.

How Can We Ensure Permanent Linkage Between The Part And Its Digital Product Passport?

While we mainly discuss the benefits of QR and datamatrix codes for connecting to MES systems or digital twins, they are also a great way to connect DPPs to parts. With our workflow, embedding the datamatrix codes directly into the part enables traceability throughout their entire lifecycle, while simultaneously reducing labelling errors. With the ESPR emphasising that labels should comply with common standards (such as GTIN, which our markings already conform to) and be displayed in an appropriate location on the part, our solutions provide an excellent holistic solution to bring the elements of the DPP together. The result: seamless connectivity between a part and its DPP, allowing for maximum value add for stakeholders.

Digital Product Passports And COP28

With COP28 bringing in a new round of global sustainability objectives, companies, governments and the public can no longer sit idle on environmental matters. However, we believe that the Digital Product Passport is a great opportunity to align sustainability and value generation across the value chain. Whether it is cost savings through improved inventory management; value generated through higher quality feedstock of recycled materials; or enabling the digitisation of manufacturing processes, the DPP should not be dismissed as just another industry regulation – it is an opportunity for competitive advantage among businesses.

References

https://data.consilium.europa.eu/doc/document/ST-9014-2023-INIT/en/pdf