Partbox

PARTBOX

Challenges

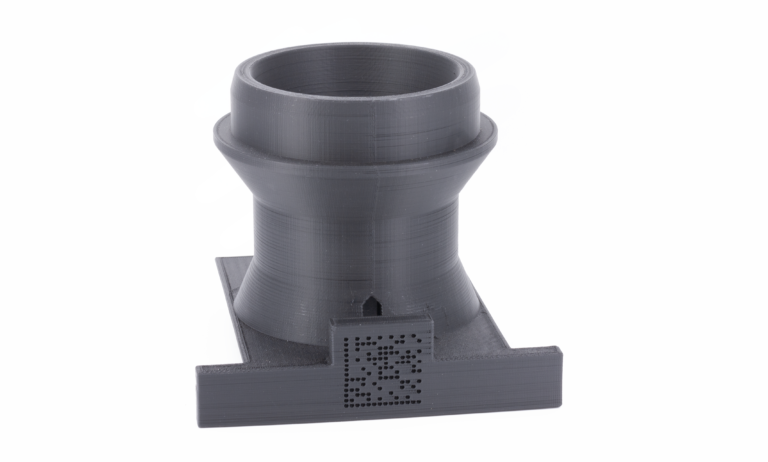

As an on-demand, part-streaming service, PartBox has a digital warehouse of qualified components for application in the packaging industry; customers can stream parts to their PartBox printer as and when they need it, replacing the need to hold physical inventory. Additionally, PartBox components have customisable features which can be adapted to suit customers’ needs, providing more flexibility than traditional manufacturing methods.

With customised parts and the need for the secure streaming of parts to PartBox printers globally, a solution for easily identifying the article number of each printed item was needed. Our integrated traceability solution therefore enables PartBox parts to not only be authenticated, but be to re-manufactured to the same parameters from the ecommerce shop system. The outcome? Improved quality control and streamlined spare part production.

Solution

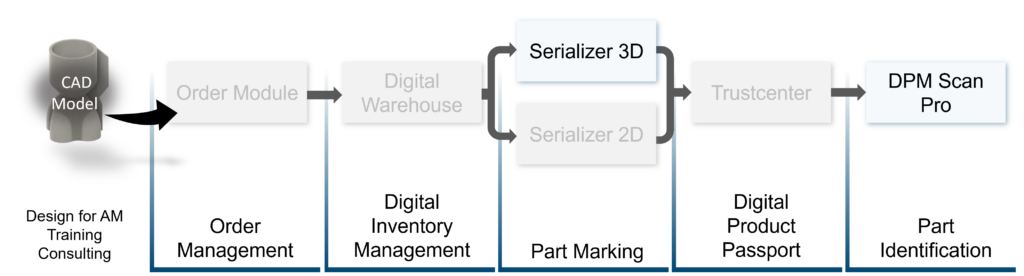

Firstly, customers edit semi-customisable parts in trinckle GmbH’s design-automation software. Once prepared, clicking “send to print” calls our API, and we convert the part (and an additional unique identifier) to machine gcode. This then enables the slicing process – the stage in Additive Manufacturing which occurs prior to printing – to be skipped. Not only does this workflow save both time and effort, it makes the 3D printing more accessible for non-experts.

Moreover, with our software integration into the PartBox platform, ordered parts are directly marked for traceability and tracked throughout the production chain. The benefits to PartBox were therefore twofold: firstly, once printed, the codes could be scanned by our DPM Scan Pro technology and the article number linked back to the PartBox shop system. Subsequently, if a part was faulty or sub-standard after production, issues with individual components could be quickly identified and rectified. Secondly, for part re-ordering, customers need only scan their marked item – again via our DPM Scan Pro technology – to access the PartBox ecommerce system. From our app, customers enter their required order quantity and rapid, on-demand spare part production is initiated. Customer data and IP security is maintained throughout the production process, and authentic, highly quality parts can be produced time and time again.

Overall, with the help of interoperable systems like in our described workflow, Additive Manufacturing can become a valuable and democratic manufacturing process which benefits all industrial sectors.