REPLIQUE

-

Carmen DeGroote

-

April 19, 2023

-

0 Comments

REPLIQUE Challenges Replique – a subsidiary of BASF and an end-to-end digital inventory platform for 3D printing – supports industries with the on-demand production of certified components. Replique sought a solution to provide customers with traceable parts with authenticating part markings and digital process documentation. Solution Through API connectivity, our Serializer was connected to Replique’s platform, allowing users to access …

Continue Reading

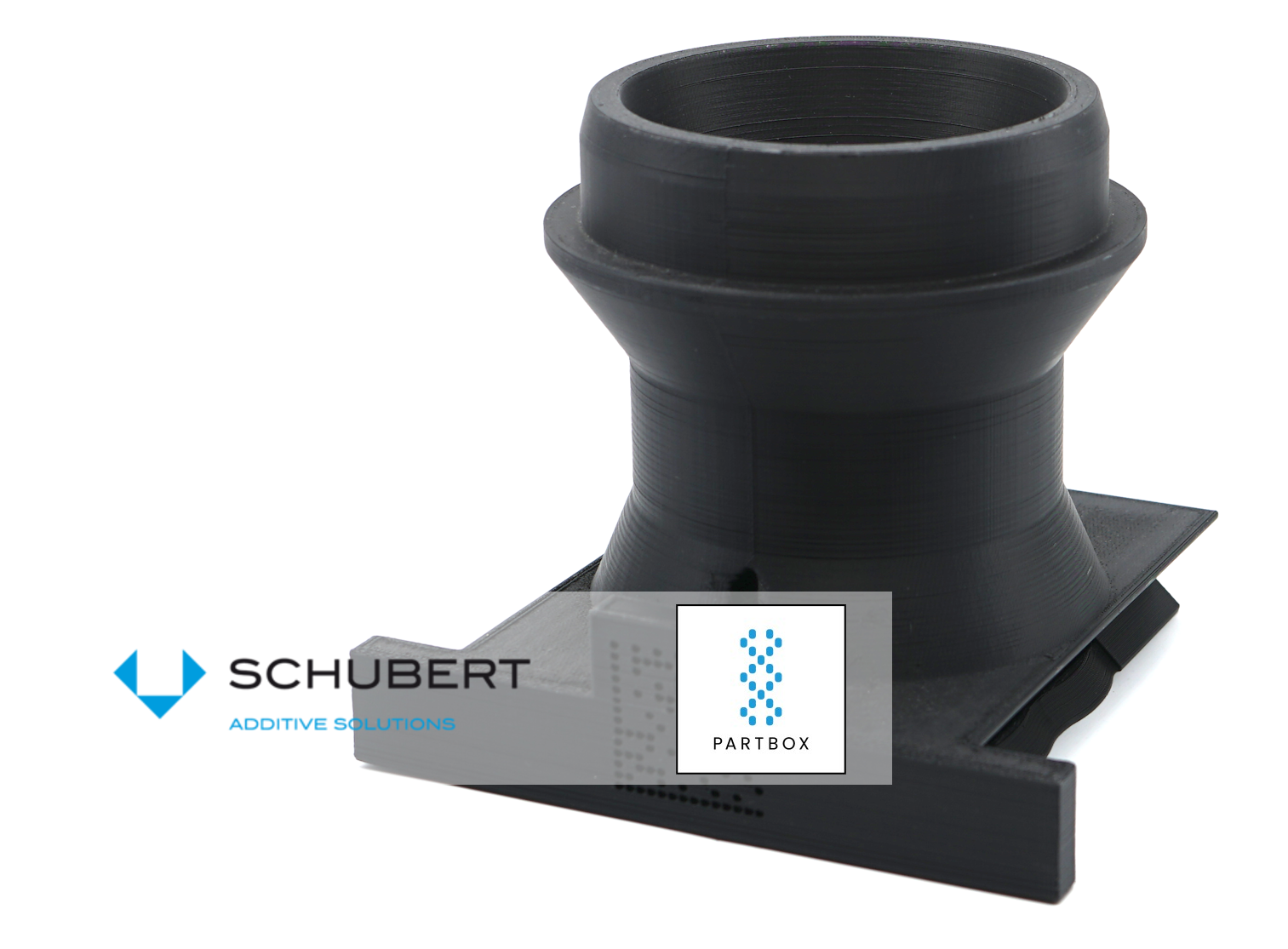

Partbox

-

Carmen DeGroote

-

April 19, 2023

-

0 Comments

PARTBOX Challenges As an on-demand, part-streaming service, PartBox has a digital warehouse of qualified components for application in the packaging industry; customers can stream parts to their PartBox printer as and when they need it, replacing the need to hold physical inventory. Additionally, PartBox components have customisable features which can be adapted to suit customers’ needs, providing more flexibility than traditional manufacturing …

Continue Reading

Materialise CO-AM

-

Carmen DeGroote

-

April 19, 2023

-

0 Comments

Materialise CO-AM https://additive-marking.de/wp-content/uploads/2023/04/CO-AM-x-Additive-Marking-Digital-Catalog-Spare-Parts-Workflow_small.mp4 Function The Materialise CO-AM platform is an industry leading order entry and shipping software for 3D printed parts production. Customers can use the portal to manage their additive manufacturing workflow, whether it is in-house, outsourced or a hybrid production strategy. The CO-AM platform offers users a variety of module add-ons to integrate different features into the 3D …

Continue Reading

Böllhoff

-

Carmen DeGroote

-

April 19, 2023

-

0 Comments

Böllhoff Challenges As an industry leader in joining and assembly solutions, Böllhoff group develop high quality fixtures for a variety of industries, including aerospace, energy and automotive. Additive Marking provided consulting on how to develop End-to-End traceability in the production of spindles for helicoils. Being small in size and having curved surfaces, the helicoild could not be labelled by conventional …

Continue Reading

TÜV NORD

-

Carmen DeGroote

-

April 19, 2023

-

0 Comments

TÜV NORD Challenges TÜV NORD are a globally recognised certification provider offering accredited testing solutions for numerous Additive Manufacturing processes. TÜV NORD are a valuable Additive Marking partner and together we have jointly established the iAM-APPROVED-platform, a digital laboratory where customers can order testing and inspection services for their Additive Manufacturing processes, according to DIN EN ISO/ASTM 52920 industrial certifications. …

Continue Reading

Solize

-

Carmen DeGroote

-

April 19, 2023

-

0 Comments

Solize SOLIZE Corporation provides 3D printing engineering services for prototypes and end-use parts in the automotive industry. The company supplies parts to Toyota and Nissan Motor Corporations, bringing the benefits of Additive Manufacturing to the automotive industry in the form of shorter lead times, reduced material costs and greater production flexibility. Challenges As an automotive contract manufacturer, SOLIZE saw end-to-end traceability as a means …

Continue Reading

Macu4

-

Carmen DeGroote

-

April 19, 2023

-

0 Comments

Macu4 Challenges Macu4 specialise in the production of forearm prostheses for outdoor activities; customers upload their measurements and order bespoke, 3D printed parts for a variety of different functions. Subsequently, each unique customer part needs to display compliance with the Medical Device Regulation (MDR) as well as a Global Trade Item Number (GTIN) for quality assurance purposes. Additionally, Macu4 wanted …

Continue Reading

CureLab

-

Carmen DeGroote

-

April 19, 2023

-

0 Comments

Cure Lab Challenge As a specialist 3D-printing contract manufacturer for medical prostheses and orthoses, Cure Lab sought a solution to enable the more streamlined and error-free handling of customer orders. Prior to implementing Additive Marking’s Solutions, Cure Lab had no centralised means of managing order requests, with information often incomplete or disparate. Through application of our Additive Manufacturing Suite (AMS), …

Continue Reading